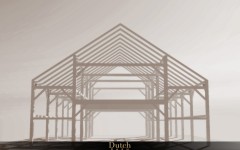

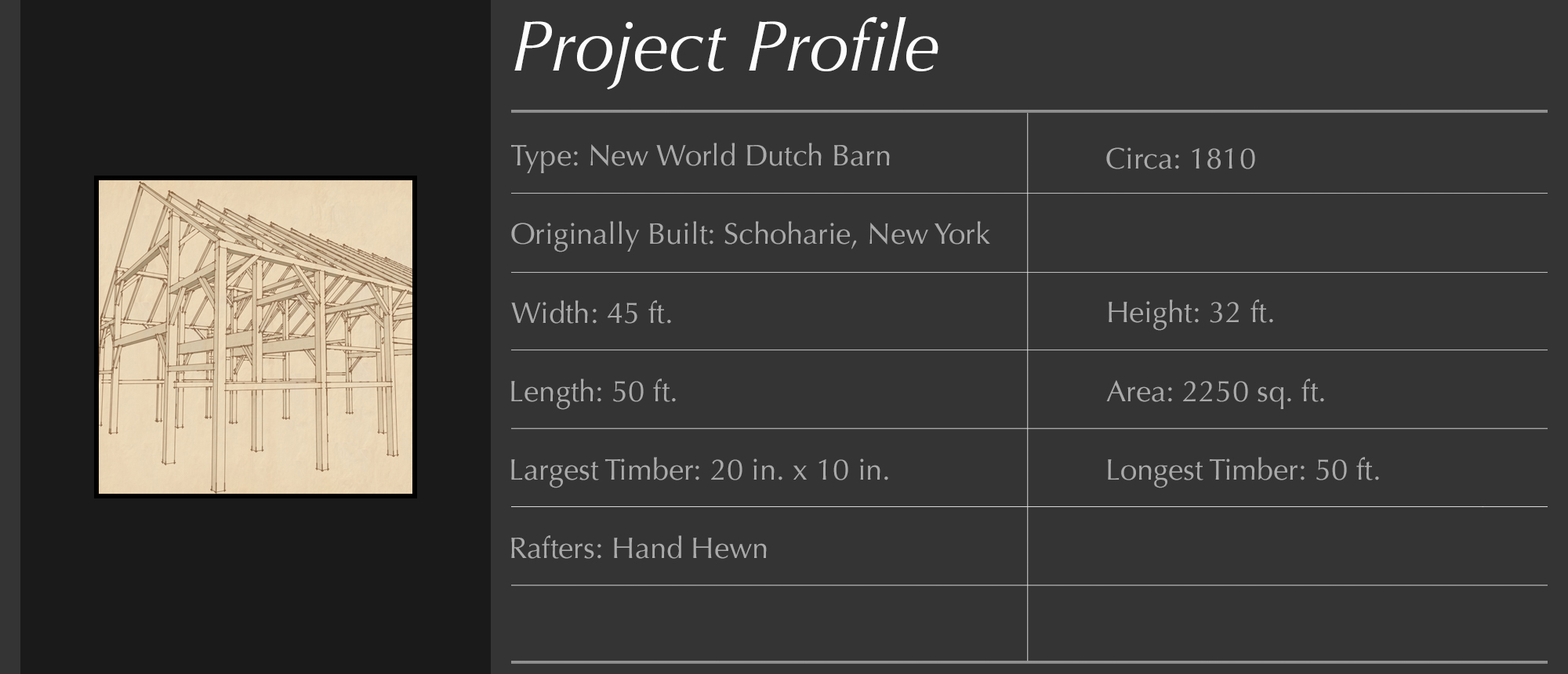

1250 Koska Dutch Barn

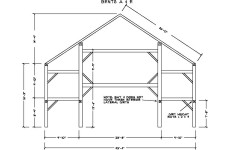

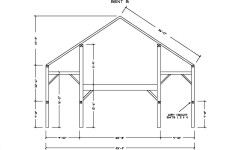

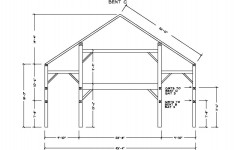

Okay, I want to say something here about what we think about hand-hewn verses sawn buildings. And even my ideas about this are getting altered by some historical facts. Here is a hand-hewn post. Probably about a twenty-five foot arcade post and all hand-hewn. So they felled this Eastern White Pine and they hewed it out with a broad ax and adz, maybe they slicked it down some; it's beautifully square. It's amazing how a person can stand on a log like this and come out with a perfectly straight hand-hewn beam. Now there are other beams in this barn that are sawn on a saw mill. Now I typically would have thought of that as later, but let's take a look at it. The parts that are sawn on a saw mill are the smaller, shorter parts. And we can date a barn, or any building for that matter, houses or mills by how they were sawn on a saw mill. And it doesn't necessarily mean a later building. But saw mills were more prevalent later in history as more mills were built and everything, but there were early saw mills even in the 1630’s in New Amsterdam they had saw mills operating. And this is hand-hewn, but notice that the beams that are hand hewn are the longest beams: 50' plates, 25' arcade posts, 25' anchor beams are hand-hewn. So what they were apparently doing was, the biggest beams, they were still hand hewing on site. They were dragging them out of the mountains, out of their lands with oxen, probably in the winter, sledding them out at a slow time of year in agriculture. And they were hewing the longest ones because they couldn't get them in a wagon, couldn't get a 50' beam down to the saw mill, so you hand hew it on site. But you can take your other shorter logs, your 16' outside wall posts, your longitudinal and lateral girts. You can get those logs down to the saw mill and have them sawn. Interesting how we can date. Now the circular saw, we can date buildings by what type of saw marks there are in the beams. Let's look over here. Here's a sawn brace and here's a sawn girt up here. Interesting, in about 1835 they invented the circular saw and it would leave circular saw kerf marks in the beams, and you can see those in later barns. This barn doesn't have that, it has straight up and down marks in it. Interesting, it was from a blade in a water powered mill going up and down like this that the logs were fed through and left vertical marks. Now if those marks on the beam were kind of angled off it’s because they were probably done on a pit saw. One man below, one on top, one down in the pit, not a very nice job, with sawdust getting in your face, but sawing through a log by hand together. A man down below like this, a man above like this and sawing through logs, sawing off boards, very early. Of course you would much rather take it to a saw mill, much easier than hand sawing. But we see these vertical marks from the up and down blade that they would feed logs through. So we can kind of date it before 1835, before those 1840-1850’s when they turned to circular blades at that time. Much easier to use, much higher production, which meant everything back then, as it does today. So we have sawn wind braces, we have sawn girts, sawn outside wall post, but on top they are capped off with fifty-some foot wall plates, purlin plates, long rafters and 30' rafters probably, all hand-hewn. Can't get them down to the mill in your wagon, so hew them on site and combine all those different elements together into a 19th century barn.