1228 Grand Gorge Barn

Interview with the Owners

Madison county couple Tim Hudson and Cindy Litsinger talk about the decision to turn a 200-year-old New York barn into their new home on property near Flora. (Joe Ellis/The Clarion-Ledger)

200-year-old barn 're-raised'

Assembling structure for home outside Flora likened to building puzzle.

By Lucy Weber

For their new house, Cindy Litsinger and fiancé Tim Hutson witnessed an old-fashioned barn-raising.

A barn that stood for close to 200 years in upstate New York was painstakingly reconstructed beam-by-beam this week on the couple’s property in the countryside outside Flora.

“Every single hand-hewn beam, all of it almost 200 years old, will be shown on the inside of the house, which is so cool to think about,” Litsinger said.

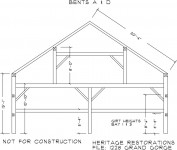

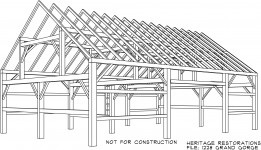

Assembled like a set of oversized Lincoln Logs, the beams form the interior bones of the almost 4,000-square-foot house. On the outside, the structure will have the shape and style of a modern day barn.

“It will look like a barn with a hayloft and cupola,” Hutson said.

On the inside, the hemlock beams — some still showing the ancient tree bark — bring to life that old Grand Gorge, N.Y., barn that stood the test of time. “The beams,” Litsinger said, “are fabulous.”

Litsinger, who has lived in two log cabins, said she and Hutson were looking up rustic houses on the Internet when they stumbled across the website of Heritage Restorations of Waco, Texas. The company finds old barns, dismantles them piece by piece, restores them and then re-erects them to their earlier states, but in new locations.

Litsinger, who owns a realty company, knew immediately that’s what their house should be. “I picked out a barn over the telephone and then we went to Waco to see the process,” she said.

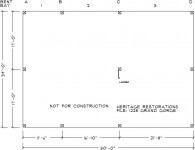

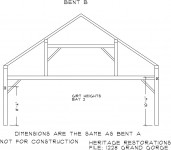

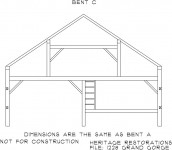

Working with the architecture firm Cisneros Design Studios in Houston, Texas, which has crafted homes around old barn structures, the couple made some modifications to the original 1820 barn. A 30-foot addition built on the barn’s backend in 1870 has been added instead on the side of the house to create the master bedroom.

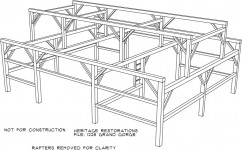

Aside from a rain delay Wednesday, a five-man crew from Heritage Restorations this week easily put together what initially looked like a large wooden puzzle scattered on the ground.

“It’s actually a really simple barn,” crew member Lemuel Brown said Thursday as they added the four top pieces that would hold the rafters.

Foreman Teb Seifu in his seven years with the company has helped re-build more than 130 aged structures. In March, he oversaw a crew re-erecting an old barn in Hattiesburg, the first one the company has done in Mississippi.

“We put them back together the way they were originally built,” he said. “Once you see it up, it’s an amazing accomplishment.”

Looking at the marks on one of the 30-foot beams, Seifu said the age of the hemlock and the skill of the craftsman is readily apparent. “Before the 1850s, they had to take a hewing axe to do this by hand. The squareness of the beam is how good the guy was doing the hewing.”

The section of the barn built in 1870 can be recognized in the sawmill cuts that created the uniformly square beams, Seifu said.

The crew uses a lot of the tools that the original builders swung a hundred or more years ago, he said. A “beetle,” an oversized mallet that weighs about 30-40 pounds, is used to pound in “treenails” or what amounts to dowels. Those, however, are new and not original to the structure, he said, since “it’s hard to save the old ones.

“You could take a sledgehammer or a big hammer but you’d never get the treenails through. You have to get it tight enough to last,” Seifu said.

First, the crew assembled the smaller support beams to the larger pieces on the ground. Then, like in a traditional barn-raising, the attached beams that form the sides are pulled up to stand in their proper places on the house’s foundation.

“Back in the day, they used an ox and a tackle, but that’s our oxen,” Seifu said, pointing to an orange and white mechanized piece of equipment driven by a crew member.

Local builder Wade Breazeale has the job of creating the house around the barn structure. While this is his first barn, he said he’s worked on log cabins before and this is similar.

“It’s a regular framing job with vaulted ceilings and no attics,” he said.

What would have been the frame for the original hayloft is the basis for the second floor that will hold two bedrooms and a bath. The downstairs family room with its fireplace will measure 34 feet by 35 feet and lie beneath a 26-foot-tall center beam. Another part of the home’s rustic charm, Litsinger said, will be seen in the heart of pine flooring that comes from an old New Orleans convent of about the same era as the barn.

Breazeale said his job is to maintain the traditional craftsmanship the original builders achieved. “They worked really hard to build this 200 years ago. We’re doing this the easy way. It’s almost like putting a puzzle together.”

Breazeale said he expects to start work Monday on the roof of the house. Litsinger said she hopes they can move in before Christmas.

Published in ClarionLedger.com (April 26, 2013).